International shipping Secure payment

No products

Prices are tax included

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

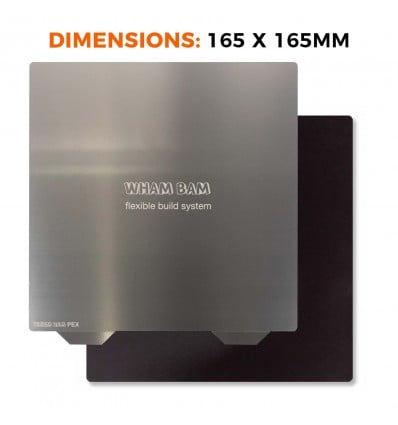

This 165x165mm Wham Bam Flexible Build System is designed with a Magnetic Base, Spring Steel Plate & PEX Build Surface for Ultimate Bed Adhesion & Convenience.

1 Item

Warning: Last items in stock!

Free shipping on orders over R1250 - courier delivery and within South Africa

Bed adhesion problems have driven Makers crazy, but we never give up on our love for 3D Printing. Fortunately, you don’t need to continue the same head-banging routine of constant tweaking and methodical print removal with clunky scrapers anymore! The Wham Bam Flexible Build System is designed to offer some of the best Bed Adhesion qualities on the market, while also offering an easy release once cooled. These build systems are uniquely comprised of three distinct pieces, with the first being a magnetic base, the next a strong (yet very flexible) spring steel plate, and the final piece of the puzzle is a beautiful PEX Build Surface. This awesome combination of parts allows you to enjoy awesome print quality from the very first layer, while the flexibility and portability of the spring steel plate means that you simply remove the plate from the magnetic bed and then “pop” the prints off with ease once they’re printed.

This Wham Bam Flexible Build System is 165x165mm, perfect for fitting the small bed of the Creality Ender 2 Pro 3D Printer. The actual build surface that sits atop the spring steel plate is made of PEX, or Cross-Linked Polyethylene. PEX has an even higher glass transition rate and melting point than popular PEI beds. This subtle but important difference leads to excellent adhesion at temperatures above 50°C and ensures that this surface doesn’t suffer from the frustrating surface bonding from over-adhesion – similar to how it happens with PEI and PETG.

These awesome conveniences and adhesion-quality features all add up to one truly amazing package, and there aren’t many other Build Systems like this that can compete with such awesome features at such a great price. So, if you’ve always loved having a removable build plate, but you’re plagued by Creality’s magnetic system losing its grip on your print bed, the Wham Bam Flexible Build System is the solution that won’t demagnetise, won’t layer shift unexpectedly, and won’t deform even after hundreds of bends, twists and flexes.

Please Note: While most Magnetic Build Surfaces typically suffer from loss of magnetism at high temperatures, these Wham Bam Build Systems have been specially designed to handle temperatures of up to 150°C without problem. So, feel free to print ABS and other high temperature filaments to your heart’s content, without having to worry about your bed slipping loose or having similar issues from the extended periods of high temperatures.

Wham Bam Flexible Build System - Technical Specifications: |

|

|

|

|

– 165 x 165mm |

|

– 162 x 162mm |

|

– Creality Ender 2 – Da Vinci Mini w+ |

|

|

|

– 1 x Wham Bam Magnetic Base – 1 x Wham Bam Flexi Build Plate – 1 x Wham Bam PEX Build Surface (Pre-Installed) – 1 x Steel Wool 000 Surface Preparing – 1 x Set of Wham Bam Stickers |

|

– PEX (Cross-Linked Polyethylene) |

|

– ≤150°C |

|

– ≤180°C |

Additional Resources:

- If you want to find out more about the different types of beds that Wham Bam offers, check out this handy Wham Bam Bed Material Selection Guide to get a better understanding of precisely what makes each material awesome in its own way.

- Additionally, just in case you’re a little confused as to how the different sizes fit different 3D Printers, we’ve also included this link to the Wham Bam Size Selection Guide too, where they have a collection of their different sized build surfaces, as well as a list of each tested and compatible 3D Printer.

Finally, the following video is a great review and build guide for the Wham Bam Flexible Build System from Teaching Tech, in which he compares it to the classic Creality CMagnet Bed, and shows off some of the key features that set it apart from competitors:

No customer reviews for the moment.

Wham Bam Systems is a funky, lively brand created by Peter Solomon, who has actually been a relatively well known inventor for 45 years now. From developing laboratory methods and protocols, to work on complex interferometer mechanisms, Peter has been applying for patents since as far back as 1984 – and now his most recent work is the reinvention of the 3D Printer Build Platform. This is how Wham Bam Systems started, and since 2019 they have been gaining popularity as some of the most effective and most convenient build plate systems on the market.

Catering to a large range of popular 3D Printers from leading hobbyist 3D Printer brands, Wham Bam Systems offers some of the best build plates on the market, and with the recent addition of the Wham Bam HotBox to their catalogue, we can’t wait to see what else Wham Bam Systems has in the pipeline for future upgrades.