International shipping Secure payment

No products

Prices are tax included

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Wear-resistant 0.5mm Plated Brass Nozzle from the world-renowned brand Micro Swiss - Designed for 1.75mm E3D V5/V6 Hotend Assemblies.

3 Items

Warning: Last items in stock!

Free shipping on orders over R1250 - courier delivery and within South Africa

While many Makers and manufacturers in the past would always consider nozzles to be somewhat standard and unimportant components in 3D Printing, the introduction of exotic and abrasive filaments has dramatically changed this, and some brands are now putting a lot of focus into nozzle design, material composition and a variety of other factors, in order to make nozzles that are more wear-resistant and consistently precise for 3D printing.

One such leading brand is Micro Swiss, and this world-renowned company taken the initiative of developing and refining high quality nozzles for all of the major 3D Printer Models, to provide customers with a collection of nozzles that offer genuine quality that they can trust. Not only are these 3D Printer Nozzles designed and manufactured to an incredible level of quality control and precision, but Micro Swiss have even refined the alloys and materials used within these nozzles in order to offer a lower friction coefficient, better wear resistance, and perfect compatibility with some of the leading Hotend Assemblies on the market.

This 0.5mm Micro Swiss Nozzle is part of their E3D range, and is designed for 1.75mm E3D V5/V6 hotend assemblies, and is made from Plated Brass, with a specialised TwinClad XT nickel-composite coating that gives it a much stronger resistance to wear and tear, while also offering less friction to reduce clogging and other similar problems associated with typical budget nozzles. These unique factors make it an excellent nozzle for printing in Exotic Filaments and abrasive polymers, but still provides great benefits even if you only print in ABS or PLA Filaments – offering an impressively long lifespan of precision and consistency.

Note: This is a Micro Swiss Original Nozzle, supplied directly by the industry leaders in nozzle R&D and Production. This ensures premium quality and lasting durability, even when dealing with high-corrosion filaments like Carbon Fiber and MetalFill.

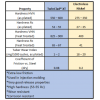

0.5mm Micro Swiss E3D Plated Brass Nozzle - Technical Specifications: |

|

|

– Micro Swiss |

|

– 360 Brass |

|

– “TwinClad XT” Nickel Composite |

|

– 1.75mm |

|

– 0.5mm |

|

– M6 |

|

|

Typical Applications for 0.5mm Micro Swiss E3D Plated Brass Nozzles:

Although brass nozzles are typically adequate for most 3D printing applications with standard filaments like ABS and PLA, some of the more exotic and unique 3D Filaments can be very abrasive due to the added materials like metal, carbon fiber or wood. For such abrasive filaments, a brass nozzle would typically wear down really quickly, leading to possible clogs and jams, as well as over-extrusion – with all of these factors negatively affecting the finished print quality. Fortunately, all you need to effectively print these kinds of filaments is a reliable high-durability nozzle like this one, making it a surprisingly affordable “upgrade” that you can equip to any 3D printer with an E3D-style V5 or V6 hotend assembly.

The 0.5mm size is slightly larger than the industry standard of 0.4mm, but still offers an excellent blend between printing speed and precision. And whilst the smaller 0.2mm Micro Swiss Nozzle is made for highly-detailed prints, and the larger 0.8mm Micro Swiss Nozzle is made for faster and less-detailed prints, this 0.5mm nozzle offers relatively good accuracy as well as good printing speed, making it great for prints that don’t need much detail or rapid turnaround times. If you're eager to get a Micro Swiss nozzle, but are looking for a larger or smaller output diameter, be sure to take a look through our entire Range of Nozzles, which are available in sizes from as small as 0.2mm all the way up to extra-large 2mm output nozzles.

Quick Guide to Changing your 0.5mm Micro Swiss E3D Plated Brass Nozzle:

When swapping out 3D Printer Nozzles from other components, we recommend utilising the hot tightening technique for optimal thermal coupling. To do this, simply follow these easy steps, while being careful not to burn yourself of course.

- Unscrew the heatbreak from the heatsink by about half a turn, to be sure you are not tightening against the heatbreak in later stages.

- Heat up your hotend to 285°C, but do not overshoot as you risk damaging your thermistor.

- Remove the existing nozzle from the heater block and insert the new nozzle.

- While firmly gripping the heater block, slowly tighten the nozzle. Be careful, however, that you not apply any torque through the heatbreak, as they are fragile and relatively easy to break when loose.

- Turn off the heating unit and allow the hot side to cool.

- Finally, once the nozzle is installed and cooled down, tighten the heatbreak back into the heatsink and ensure that there are no loose parts.

The reason for this is that aluminium heater blocks have a different coefficient of thermal expansion than the materials used in the nozzles and heat breaks. This results in a small gap being created between the nozzle and the break inside the block when the hot end is at temperature, but this only happens if the nozzle has been tightened while cold.

The following is a great instructional video on how to change your nozzle without damaging your heatsink:

No customer reviews for the moment.

Within 3D Printing, there are a few brands whose hard work has made them stand out from the rest, with real innovation and the ability to not only refine old designs, but actually redesign from the ground up to offer more comprehensive upgrades for 3D printing enthusiasts and Makers throughout the world.

Micro Swiss is one such brand that perfectly fits this description, and since their founding back in 2015, the Micro Swiss brand has garnered world-wide attention for the quality, material composition and precision of their hotends, nozzles and other all-metal components. With a core focus on TwinClad XT Plated Brass Nozzles and All-Metal Hotend Upgrades for some of the most popular 3D Printers on the market, it’s no surprise that one of the easiest and most effective upgrades available to Makers are Micro Swiss Replacement Parts and Upgrade Kits.

In addition to the amazing 3D Printing components and upgrades that they produce, Micro Swiss also specialise in Swiss Turning, which is capable of precision CNC machining outer diameters as small as 0.0127mm, as well as CNC milling, tapping and post machining finishing for prototyping. These service offerings and correlating skillsets ensure that the Micro Swiss team is more than just capable of producing consistently high-quality parts, but also capable of identifying precisely where each part could use improvements.

As manufacturers and end-users of everything they produce, Micro Swiss is one of the most impressive brands we’ve had the pleasure of dealing with, and we look forward to all of the exciting refinements and developments that they are bound to bring out in the future.