International shipping Secure payment

No products

Prices are tax included

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

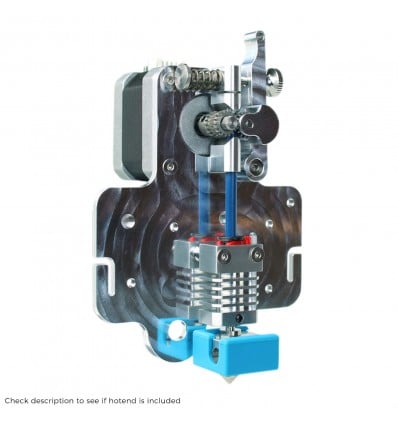

Step up your 3D Printing game & step into a whole new world of exciting polymers & filaments with this exceptional quality Micro Swiss DDS Extruder.

4 Items

Warning: Last items in stock!

Free shipping on orders over R1250 - courier delivery and within South Africa

As any proud owner of a beautiful machine from the Creality Ender 5 Range of 3D Printers will know, these amazing machines are more than just capable of producing incredible quality prints, although until quite recently, there haven’t been too many cool Kits & Upgrades for the Ender 5 Series, and that’s why we’re more excited than usual for the cool new Micro Swiss Direct Drive Extruder for the Creality Ender 5, Ender 5 Pro and Ender 5 Plus. This upgrade is designed to an exceptional level of quality – which Micro Swiss are famous for – and is built to offer both high durability and extremely low weight for direct drive 3D Printing. It is built to be as simple to install as possible, with the included Micro Swiss Hotend Assembly adding further to this convenience and the level of quality you can expect, and is ready to help you step up your 3D Printing game, while also stepping into a whole new world of unique polymers and exciting filaments.

Crafted by the masters of the Swiss Lathe, Micro Swiss, and designed for one of the most impressive Hobbyist 3D Printers in the world, this upgrade is designed to help you turn your Creality Ender 5 Series 3D Printer into a Direct Drive 3D Printer, to replace (and upgrade) the original Bowden setup that comes installed on these already-fantastic machines. This allows you to really get out of your typical comfort zone in 3D Printing, so you can challenge yourself with polymers like CCTREE Flexible TPU, eSUN eLastic TPE, or even the world famous NinjaFlex Range of Flexibles – except without the common tangling, hysteresis and other Bowden-associated issues getting in your way. Of course, even if you don’t plan on 3D Printing in TPU and other flexibles, a reliable direct drive extruder like this does offer a lot of cool benefits, from a higher level of precision to more control over retraction, and these features will undoubtedly improve print quality regardless of what 3D Filaments you’re using, making it a valuable upgrade for all kinds of 3D Makers from artists to engineers and everyone in between.

It must be noted, however, that although we simply love this extruder upgrade, we also know that it’s not going to be for everyone, so be sure to check out the final paragraph of this description to get a better understanding of whether this upgrade is a good choice for you.

Important Note Directly from Micro Swiss: We notice a recent extruder stepper motor update on Creality machines. Before ordering this kit, please check your extruder stepper motor. If your extruder motor gear is pressed in, you will need to purchase a new stepper motor to be able to complete the installation.

Micro Swiss Ender 5 / 5 Plus Direct Drive Extruder - Technical Specifications: |

|

|

|

|

|

|

– Machined Aluminium |

|

– Hardened Tool Steel |

|

– Dual Drive Gears |

|

– NEMA 17: 5mm Shaft |

|

|

|

– 1.75mm |

|

– 130 steps/mm |

|

– 1.5mm @ 35mm/s |

Parts Included with the Micro Swiss Ender 5 / 5 Plus DDS Extruder: |

|

|

|

|

|

|

|

|

|

|

|

|

|

Please Note: This kit does not include a stepper motor or roller wheels for mounting this carriage onto the Gantry. Fortunately, you can simply use the stepper motor and roller wheels you currently have, which of course saves you from unnecessary extra cost.

Is this Micro Swiss Direct Drive Upgrade a Good Choice for You?

Here at DIYElectronics, we strive to stock a good selection of 3D Printer Upgrades and Kits for improving your 3D Printing experience, and the benefits of such upgrades are usually obvious from the outset. However, with this direct drive upgrade system, the benefits are not immediately obvious, and the value of these benefits will vary depending on your 3D Printer setup, as well as what you really want from your 3D Printer. This is because a direct drive setup is technically not better or worse than a Bowden setup, but instead just offers slightly different benefits while also having its own unique drawbacks – and this of course is why there are often debates going on within online forums about which is better, with passionate evangelists for both sides.

With this in mind, and as a means to provide some unbiased clarity on the topic (we like both Direct Drive and Bowden setups), we have found from personal experience that the key differences between the two styles is that a Bowden Setup focuses on low weight, high speed and good accuracy at high speeds, whilst Direct Drive Setups focus more on pinpoint precision, fine filament control and reduced power-loss through the various components. This is primarily why so many PLA-focused 3D Printers will utilise the Bowden setup, as it offers the best speeds for producing good quality prints at a rapid pace, but if you want to start venturing into trickier filaments such as Flexibles, you may start struggling due to the hysteresis (or lagging motion) and noise from the many Bowden components transferring power over a reasonably long distance.

Conversely, Direct Drive is the setup of choice for anyone who loves printing in Flexible Filaments or trickier filaments, as it has a much more constrained filament feed-path than Bowden setups, as well as a close proximity between the driving gear and the motor. This translates to much finer filament control, as the driving motor doesn’t have to push and pull the filament down a long pipe, and instead the driving motor can almost directly grip the filament, reducing potential noise between components, drastically reduced lag in motions, and what can be technically be considered faster retraction times. This kind of setup doesn’t give the filament much wiggle room (quite literally), meaning that flexibles and other tricky filaments can’t tangle, snake around gears or cause similar spaghetti-like problems.

So as you can see, choosing between direct drive and Bowden is really just a matter of what you want from your 3D Printer, and if you’ve always loved the capabilities of direct drive 3D Printers like our Prusa i3, but simply can’t resist the massive build volume of Bowden 3D Printers like the Creality CR-10 and Ender series, then this direct drive upgrade kit is the ideal upgrade to give you the very best of both worlds.

Additional Resources:

- If you are interested in upgrading to a direct drive setup, but aren’t exactly sure if it would benefit you or not, check out this helpful MatterHackers Extruders 101 Crashcourse, as well as this Bowden vs Direct Drive Guide from Fargo3DPrinting, which both cover the benefits and drawbacks of Direct Drive and Bowden setups, to help users understand which is better for their 3D Making and fabrication applications.

- As per usual, Micro Swiss have done an excellent job at not only manufacturing a truly beautiful and functional 3D Printer Upgrade, but also at documenting everything in an easy to understand way. As such, this Micro Swiss Ender 5 / 5 Plus DDS Upgrade Installation Guide is a great tool for seeing what the installation process involves, and what steps you will need to take to upgrade your Creality 3D Printer with an awesome new direct drive extrusion setup. We have also included this in the downloads section above.

Finally, the following video from ModBot is an awesome demonstration of precisely what’s required when installing this DDS extruder system onto a Creality Ender 5 3D Printer. if you need further information before giving in to the urge to upgrade your already-awesome 3D Printer, or if you’re just eager to see what this installation process entails, be sure to check it out:

Simple and Sweet

Took about 2 hours to assemble, if you have an Ender 5 and don't have this then you have an incomplete 3D printer. The moment you do this swop you notice immediate improvements of quality and finish (Remember to change the Esteps to 130 and use the extension cable that came with the kit as your extruder motor will turn in the incorrect direction if you don't)

Within 3D Printing, there are a few brands whose hard work has made them stand out from the rest, with real innovation and the ability to not only refine old designs, but actually redesign from the ground up to offer more comprehensive upgrades for 3D printing enthusiasts and Makers throughout the world.

Micro Swiss is one such brand that perfectly fits this description, and since their founding back in 2015, the Micro Swiss brand has garnered world-wide attention for the quality, material composition and precision of their hotends, nozzles and other all-metal components. With a core focus on TwinClad XT Plated Brass Nozzles and All-Metal Hotend Upgrades for some of the most popular 3D Printers on the market, it’s no surprise that one of the easiest and most effective upgrades available to Makers are Micro Swiss Replacement Parts and Upgrade Kits.

In addition to the amazing 3D Printing components and upgrades that they produce, Micro Swiss also specialise in Swiss Turning, which is capable of precision CNC machining outer diameters as small as 0.0127mm, as well as CNC milling, tapping and post machining finishing for prototyping. These service offerings and correlating skillsets ensure that the Micro Swiss team is more than just capable of producing consistently high-quality parts, but also capable of identifying precisely where each part could use improvements.

As manufacturers and end-users of everything they produce, Micro Swiss is one of the most impressive brands we’ve had the pleasure of dealing with, and we look forward to all of the exciting refinements and developments that they are bound to bring out in the future.

Micro Swiss

Well, I for one have never been overly exited about "made in America" But I might just be a converted fan-boy as off right now....

As a "techie" I can not help loving the micro swiss direct drive extruder. (well, this applies to all their product really)

What really impressed me (after I got over the enjoyment of holding what is an piece of engineering artwork) is how they address all the small things that I've always through needs improving in 3Dprinters with E3D hotends and generic extruders.

Some examples:

1) extra "teeth" on the extruder gears to ensure the gear and idler-gear both turns (instead of just relying on the friction of the filament between the two)

2) If we look at the heat-break - they are always a pain to unscrew, Micro Swiss let's you slot it in place and then use a grub screw to keep it in place.

In short - if you are building or upgrading and you are not going with Micro Swiss, you are doing it wrong.