International shipping Secure payment

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Free shipping on orders over R1250 - courier delivery and within South Africa

- Hide

- Home

- 3D Printing

- Filament

- 3D Resin

- Electronics

- Mechanics / CNC

- Tools / Other

The Micro Swiss FlowTech Hotend shakes up their all-metal design for high-flow 300°C printing and upgrades your Creality Ender 3 V3 KE with a leak-proof nozzle.

Free shipping on orders over R1250 - courier delivery and within South Africa

Having garnered world-wide attention for their quality and passion for precision, Micro Swiss manufacturers innovative upgrades for many 3D printers. This American company utilises a Swiss lathe to reach a precision rating of up to 0.005mm tolerances, and we are always excited to check in on their latest developments of hotends, extruder assemblies, and 3D printer components.

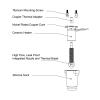

Sparking a new generation of inspired Micro Swiss Hotends, the FlowTech Hotend assembly is a perfect drop-in upgrade for the Creality Ender 3 V3 KE. The impressive design shakes up what we’ve seen before from Micro Swiss and doubles the quality. The Micro Swiss FlowTech has a unique ceramic cylindrical heater and 28.6mm melt zone that prioritises smooth filament flow at the high speeds of the K1 and Ender 3 V3 KE printers. Truly optimise your printer and get the results you’re looking for quick as a whip.

Micro Swiss boasts remarkable features that eliminate common hotend issues that slowdown your printing frenzies. The FlowTech Hotend sports a leak-proof nozzle that combines the nozzle and thermal break into one sealed assembly. This ensures stray filament can’t ooze out and cause messy nozzle leaks that ruin your prints and waste precious filament. The nozzle also allows for swapping out effortlessly while the hotend stays cold. Switch your nozzle out with one hand and no need for hot tightening. With all these upgrades and high-flow 300°C printing, the Micro Swiss FlowTech Hotend is a no-brainer if you want to take your Creality Ender 3 V3 KE to the peak of efficiency.

Micro Swiss FlowTech Hotend – Technical Specifications: |

|

|

|

|

– 0.4mm Micro Swiss FlowTech Brass Plated Nozzle |

|

– Ceramic FlowTech Heater Core |

|

– Integrated with FlowTech Nozzle |

|

– None / Not Necessary with All-Metal Design |

|

– Not Necessary with All-Metal Design |

|

– Included |

|

– -45° to +300°C |

|

– Thermal Insulation Sock Included |

|

– Titanium Mounting Screws – Copper Thermal Adapter – Nickel Plated Copper Core |

|

|

No customer reviews for the moment.

Within 3D Printing, there are a few brands whose hard work has made them stand out from the rest, with real innovation and the ability to not only refine old designs, but actually redesign from the ground up to offer more comprehensive upgrades for 3D printing enthusiasts and Makers throughout the world.

Micro Swiss is one such brand that perfectly fits this description, and since their founding back in 2015, the Micro Swiss brand has garnered world-wide attention for the quality, material composition and precision of their hotends, nozzles and other all-metal components. With a core focus on TwinClad XT Plated Brass Nozzles and All-Metal Hotend Upgrades for some of the most popular 3D Printers on the market, it’s no surprise that one of the easiest and most effective upgrades available to Makers are Micro Swiss Replacement Parts and Upgrade Kits.

In addition to the amazing 3D Printing components and upgrades that they produce, Micro Swiss also specialise in Swiss Turning, which is capable of precision CNC machining outer diameters as small as 0.0127mm, as well as CNC milling, tapping and post machining finishing for prototyping. These service offerings and correlating skillsets ensure that the Micro Swiss team is more than just capable of producing consistently high-quality parts, but also capable of identifying precisely where each part could use improvements.

As manufacturers and end-users of everything they produce, Micro Swiss is one of the most impressive brands we’ve had the pleasure of dealing with, and we look forward to all of the exciting refinements and developments that they are bound to bring out in the future.